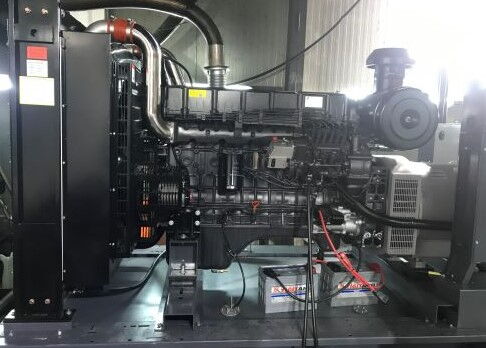

In today's society, the stability of power supply is crucial for the normal operation of businesses, institutions, and critical infrastructure. Diesel generator sets, as reliable backup power sources, can quickly provide electricity during outages, ensuring that essential equipment and systems remain operational. However, to guarantee stable generator output, proper wiring is an indispensable step. This article provides a comprehensive guide on the wiring of diesel generator sets, covering key points, maintenance practices, and wiring methods for different types of generators, helping readers safely and efficiently complete this critical task.

Before starting the wiring process for a diesel generator set, several essential preparations must be made:

- Involvement of Professional Personnel: Wiring should always be performed by experienced, qualified electricians. This is because generator wiring involves complex electrical knowledge and strict safety regulations. Improper handling by non-professionals can lead to serious accidents, such as electric shock or fire. Qualified electricians not only possess professional electrical expertise but also are familiar with relevant electrical standards and codes, ensuring that wiring is performed safely and reliably.

- Understanding Electrical Standards and Requirements: Generator wiring must comply with local electrical standards, including grounding and protection against ground faults. Grounding is a critical component of any electrical system; it prevents electric shock and ensures that in the event of a fault, the power supply is cut off to protect both personnel and equipment. Therefore, before beginning wiring, it is essential to thoroughly study and understand local electrical codes and standards to ensure compliance.

- Inspection of Equipment and Materials: Prior to wiring, a comprehensive inspection of the generator set should be conducted to confirm it is in proper working condition. Electrical wires, cables, junction boxes, and other materials must also be checked for quality and specifications. The gauge, material, and type of wire all influence generator performance and safety, so only appropriate, high-quality wiring should be used.

Once preparatory work is complete, the next step is the critical wiring process. Proper wiring is not just a step in installation; it is foundational for stable operation and optimal performance. Adhering to correct wiring practices ensures that the generator set can safely and efficiently deliver power under all conditions. Key points include:

Generators generate vibration during operation, so flexible wires should be used to connect the generator. Flexible wires prevent damage to the alternator or the terminals of the power circuit breaker if the generator shifts. If flexible wires cannot be installed due to space constraints, a junction box should be installed near the generator, with a flexible wire segment connecting the junction box to the generator.

When routing wires, they must be installed in conduits or cable trays and should never be directly fastened to the generator. Bends should follow the minimum bending radius to prevent damage.

Wire gauge selection requires consideration of multiple factors: generator voltage and current output, ambient temperature, installation method, and proximity to other wires. For single-core copper wires, insulation and sheathing materials can include non-magnetic metals (aluminum or copper) or non-metallic materials such as Teflon. If magnetic metal sheaths are used, they must have slots to prevent eddy currents, which could generate heat and damage the wires.

Circuits connecting the generator to the load should be protected by circuit breakers. These devices automatically cut off power in the event of overloads or short circuits, protecting both the generator and connected equipment.

During system design, load balance must be carefully considered to avoid overloading any single phase. Excessive load on one phase can overheat the alternator coils and damage the generator. Unbalanced three-phase loads can also harm sensitive three-phase equipment. Load distribution must be calculated to keep current differences between phases within allowable limits.

Load power factor is another consideration. A lagging power factor below 0.8 can overload the generator. Ideally, generators should operate within a power factor range of 0.8 to 1.0. When using automatic or manual power factor correction devices, care must be taken to avoid leading power factors, which can destabilize voltage and create dangerously high voltages. Power factor correction devices should be turned off during normal generator operation.

The grounding point of a diesel generator set is typically located at the end of the generator chassis. Proper connection to a reliable ground is crucial. The neutral point of the alternator is usually determined by the user during installation. If the generator is the sole power source, the neutral must connect directly to the facility's grounding system.

In complex installations, a proper grounding midpoint may be used to detect ground faults and minimize circulating ground currents. Grounding layout should follow recommendations from both the user and local authorities to ensure safety and effectiveness.

After mastering the basic principles of generator wiring, it is important to understand the specific wiring methods for different types of diesel generator sets. Wiring differs depending on the generator's features and level of automation.

Conventional generators usually lack an automatic transfer switch (ATS), requiring manual switching to connect the generator to the load. The output terminals typically use a three-phase four-wire configuration with U, V, W, and N terminals. For a 380V system, the three phase lines are connected to U, V, W. After starting the generator, once the voltage reaches approximately 400V and frequency stabilizes near 50Hz, the load circuit breaker can be closed.

Many operators neglect to monitor voltage and frequency after load connection, which is dangerous. Correct practice involves monitoring the instruments; if voltage or frequency drops, the generator throttle should be increased to stabilize output.

For brushed alternators, the load breaker should be opened first when shutting down, allowing the generator to idle for a few minutes before stopping. This prevents demagnetization of the alternator and ensures sufficient cooling for the engine, prolonging equipment life.

These generators also lack ATS switches but offer enhanced protection, intuitive monitoring, and simplified one-button start operation. Wiring is similar to conventional generators, but the start procedure is automated. Operators can easily adjust voltage and frequency via the control screen, enabling rapid startup and load connection.

Shutdown procedures remain the same: disconnect the load first, then allow the generator to idle before turning off, protecting brushed alternators and ensuring proper cooling.

Fully automatic generators have more complex wiring but offer high intelligence and automation. These systems integrate 220V mains with control cabinet signal lines. The control system monitors mains power, automatically starting the generator during an outage and switching the load circuit to generator power.

Load cables must be pre-connected according to the ATS phase sequence to ensure seamless power transfer during outages. Fully automatic systems enable automatic startup, load switching, and shutdown. Once mains power returns, the system reconnects the load to mains and stops the generator. These generators are ideal for critical applications such as hospitals, data centers, and communication base stations. Proper setup and periodic inspection of control cabinet wiring are essential to maintain reliable operation.

After wiring, ongoing maintenance is essential to extend generator lifespan, improve efficiency, and ensure reliability. Key maintenance tasks include:

- Regular Wiring Inspections: Regularly check wiring for secure connections, absence of damage, and intact insulation. Replace any damaged wires or deteriorated insulation to prevent electric shock or short circuits. Ensure junction boxes are neatly wired and well-ventilated to prevent moisture or dust accumulation.

- Keep Equipment Clean: Maintaining a clean environment for the generator is critical. Dust and debris accumulation can impair cooling and performance. Clear surrounding areas to ensure proper airflow, and use appropriate cleaning tools and agents to avoid damaging the equipment.

- Inspect and Replace Wear Parts: Routine inspection of consumables and wear parts, such as air filters, oil filters, and fuel filters, is necessary to ensure smooth engine operation. Check belts, fans, and other components for wear, replacing them as needed to avoid malfunctions.

- Regular Performance Testing: Conduct periodic performance tests to check output voltage, frequency, and power. Simulate various loads to ensure the generator performs reliably under all conditions and to detect potential issues early.

- Follow Manufacturer Guidelines: Always adhere strictly to the maintenance instructions provided by the manufacturer. These guidelines specify maintenance intervals, procedures, and precautions. For any issues, consult the manufacturer or qualified professionals rather than attempting unauthorized repairs, which could compromise safety.

Wiring a diesel generator set is a complex yet critical task that directly affects operational safety and efficiency. Proper wiring should be carried out by professional electricians following relevant standards and regulations. The wiring method must match the generator type and operational requirements. Post-wiring maintenance is equally important to ensure longevity, efficiency, and reliability. Through correct wiring and regular upkeep, diesel generators can provide stable and dependable power supply for various applications. Whether it is a conventional, one-button start, or fully automatic generator, careful attention to wiring and maintenance is essential. This guide aims to equip readers with a comprehensive understanding of diesel generator wiring and care practices, ensuring safe and efficient operation.